- +91 8755922449

- connect2tepl@gmail.com

CLEANROOMS

HOME > CLEANROOMS

Cleanrooms

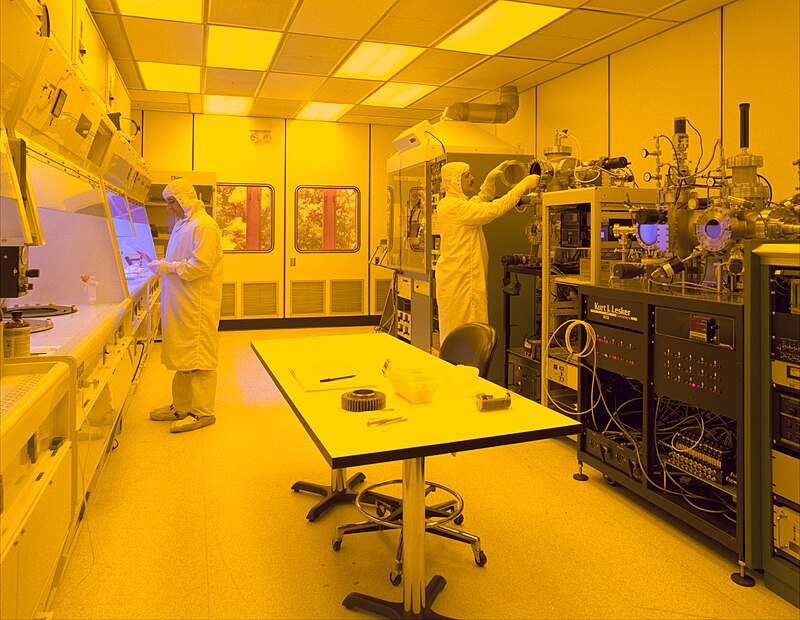

Cleanrooms are controlled environments designed to minimize the presence of contaminants such as dust, airborne microbes, aerosol particles, and chemical vapors. They are essential in industries where even microscopic levels of contamination can compromise the quality, safety, or performance of a product or process.

Features of Cleanrooms

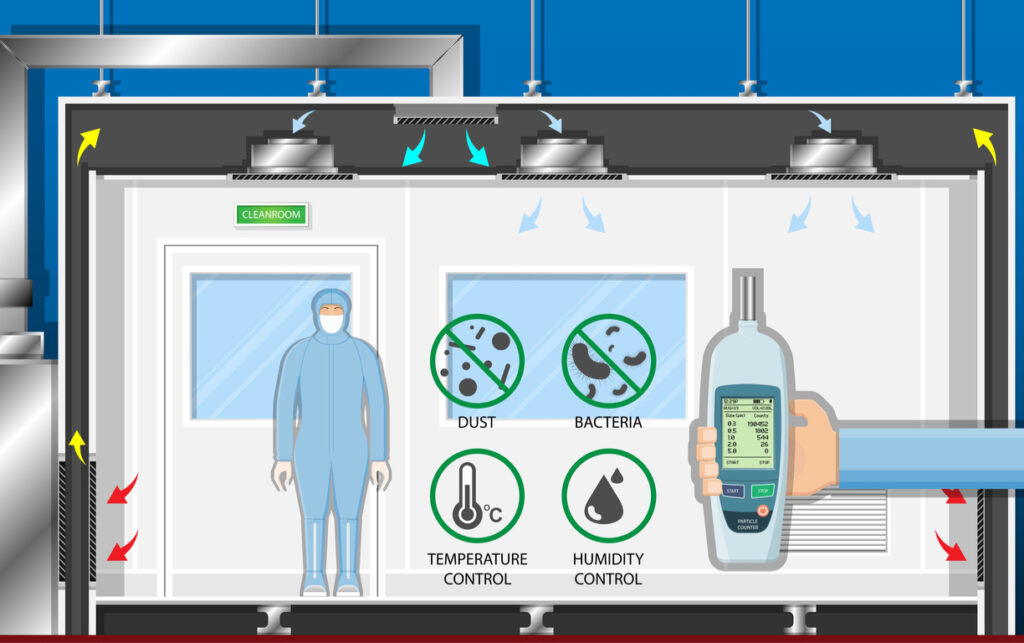

Controlled Environment:

- Temperature, humidity, and pressure are carefully regulated.

- Airborne particles are filtered using High-Efficiency Particulate Air (HEPA) or Ultra-Low Penetration Air (ULPA) filters.

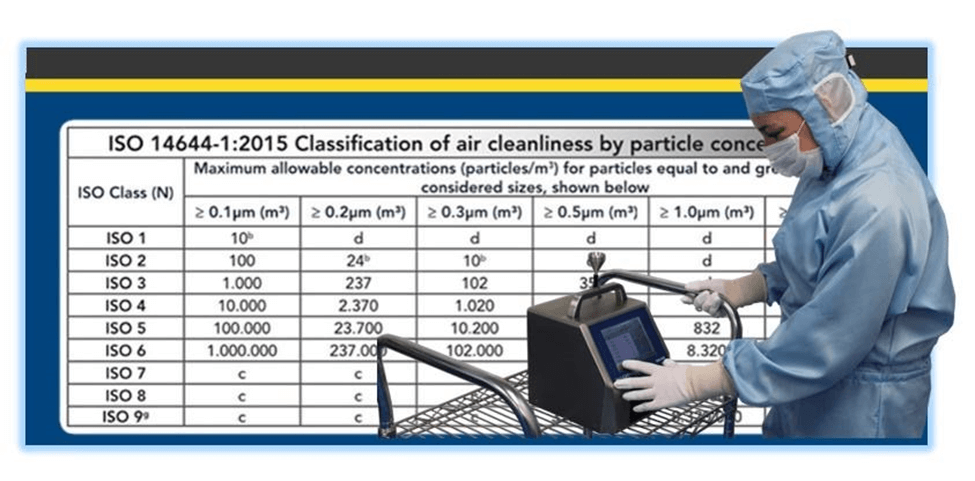

Classification:

- Cleanrooms are classified by the number and size of particles allowed per cubic meter of air, as per standards like ISO 14644-1 or the U.S. Federal Standard 209E.

- For example, an ISO Class 1 cleanroom has stricter particle limits than an ISO Class 8 cleanroom.

Personnel and Equipment:

- Temperature, humidity, and pressure are carefully regulated.

- Airborne particles are filtered using High-Efficiency Particulate Air (HEPA) or Ultra-Low Penetration Air (ULPA) filters.

Airflow Design:

- Laminar (unidirectional) or turbulent (non-unidirectional) airflow systems are used to control particle movement.

- Positive pressure prevents the entry of contaminated air from adjacent spaces.

Cleaning and Maintenance:

- Regular cleaning protocols using approved disinfectants ensure minimal microbial and particulate presence.

- Equipment is routinely tested and calibrated to maintain standards.

Applications of Cleanrooms:

Pharmaceutical Industry:

- Production of sterile drugs, vaccines, and other medical products.

Electronics and Semiconductor Manufacturing:

- Assembly of microchips, sensors, and other precision components.

Aerospace:

- Construction of spacecraft and satellites.

Healthcare:

- Operating rooms and laboratories for sensitive medical testing.

Biotechnology:

- Research and production involving cell cultures, genetic material, and biologics.

Useful Links

Copyright @ 2024 Tectivity Engineering . All Rights Reserved.

Developed By: Dizi Global Solution